A Construction Guide To

Asphalt Testing

If your work relies on asphalt testing, this comprehensive guide is for you.

In this guide, we’ll walk you through the full asphalt testing process — from sampling to strength analysis — so you know exactly what to expect and how testing ensures your project’s success.

On-Site Sampling | Binder Content | Bulk Density | Marshall Stability | Marshall Flow | Gyratory Compaction | Softening Point | Elastic Recovery | Bitumen Viscosity | MMLS

REACH OUT

What is Asphalt Testing?

Asphalt testing is the process of evaluating asphalt mix designs and pavement layers to ensure that road surfaces perform safely and durably under pressure, temperature, and traffic.

This testing verifies the structural integrity and performance characteristics of asphalt used in roads, highways, airfields, and parking areas. It helps ensure that pavements resist deformation, cracking, and ageing — and that they meet client and regulatory specifications.

Roadlab provides accredited asphalt testing services both in our laboratories and on-site, supporting road authorities, contractors, and engineering consultants across Southern Africa.

Surface, Structural Reliability

Validates strength, texture, and compaction quality.

Binder & Mix Composition

Confirms the mix design, density, and binder content.

Specification & Safety Compliance

Ensures conformity with SANAS, SANS & project specs

The Reality of Asphalt Testing

Roadlab’s asphalt and materials testing isn’t just about compliance — it’s about building real infrastructure that South Africans drive, walk, and work on every day.

Our teams have tested asphalt compaction on national highways, verified binder performance on municipal resurfacing projects, and supported contractors during the construction of solar power plants, bridge decks, and airport taxiways.

Every test contributes to safe, long-lasting infrastructure that meets regulatory expectations and public need.

When roads hold up to freight loads and heat waves, or when repaired surfaces resist rutting and cracking over time, our lab and on-site tests are part of that success.

National Roads and Highways

Supporting the public road network of South Africa.

Major Works Using Asphalt

Airports runways, major seaports and mine infrastructure.

Private Roads and Pavement Works

Access roads and private works using asphalt.

On-Site Investigations

On-site asphalt testing provides immediate feedback on material quality and construction processes during roadworks.

Tests such as extracting and testing core samples from compacted asphalt layers allow engineers to assess whether asphalt mixtures are compacted correctly and meet layer thickness requirements.

Additional tests like, Marvill permeability, IRI, MMLS & Rolling straight edge help confirm that the asphalt conforms to design and construction specifications, ensuring early detection of potential issues like under-

compaction, incorrect binder content, rutting & rideability.

By conducting these tests on-site, project teams can make timely adjustments and prevent costly failures or rework.

On-site testing is essential for maintaining control over quality during all phases of construction.

Sampling (HMA, Slurry, Emulsions, Binders)

Field collection of material for lab analysis.

Rolling Straight Edge

Measures road surface evenness and deflection.

FWD (Falling Weight Deflectometer)

Measure pavement deflection response.

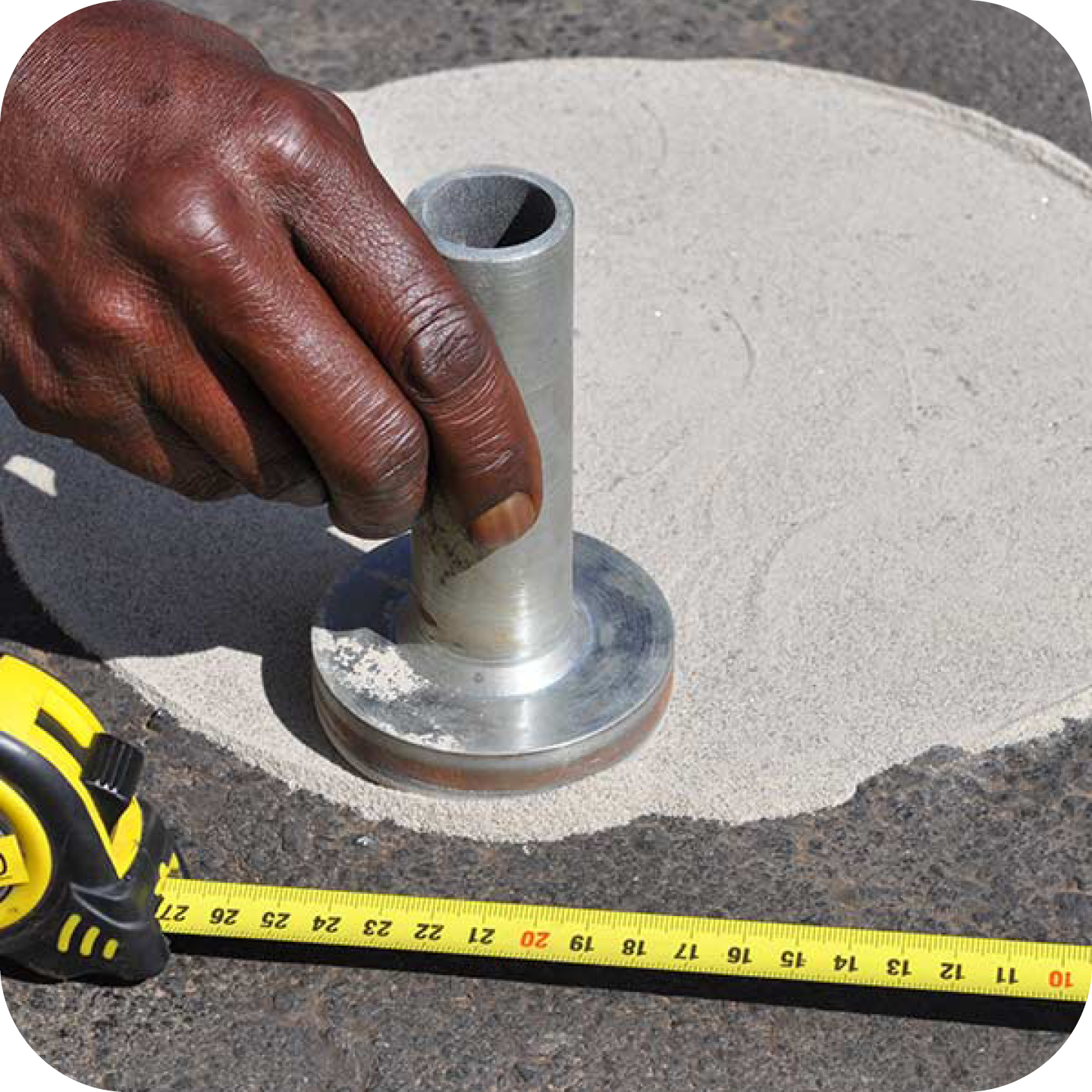

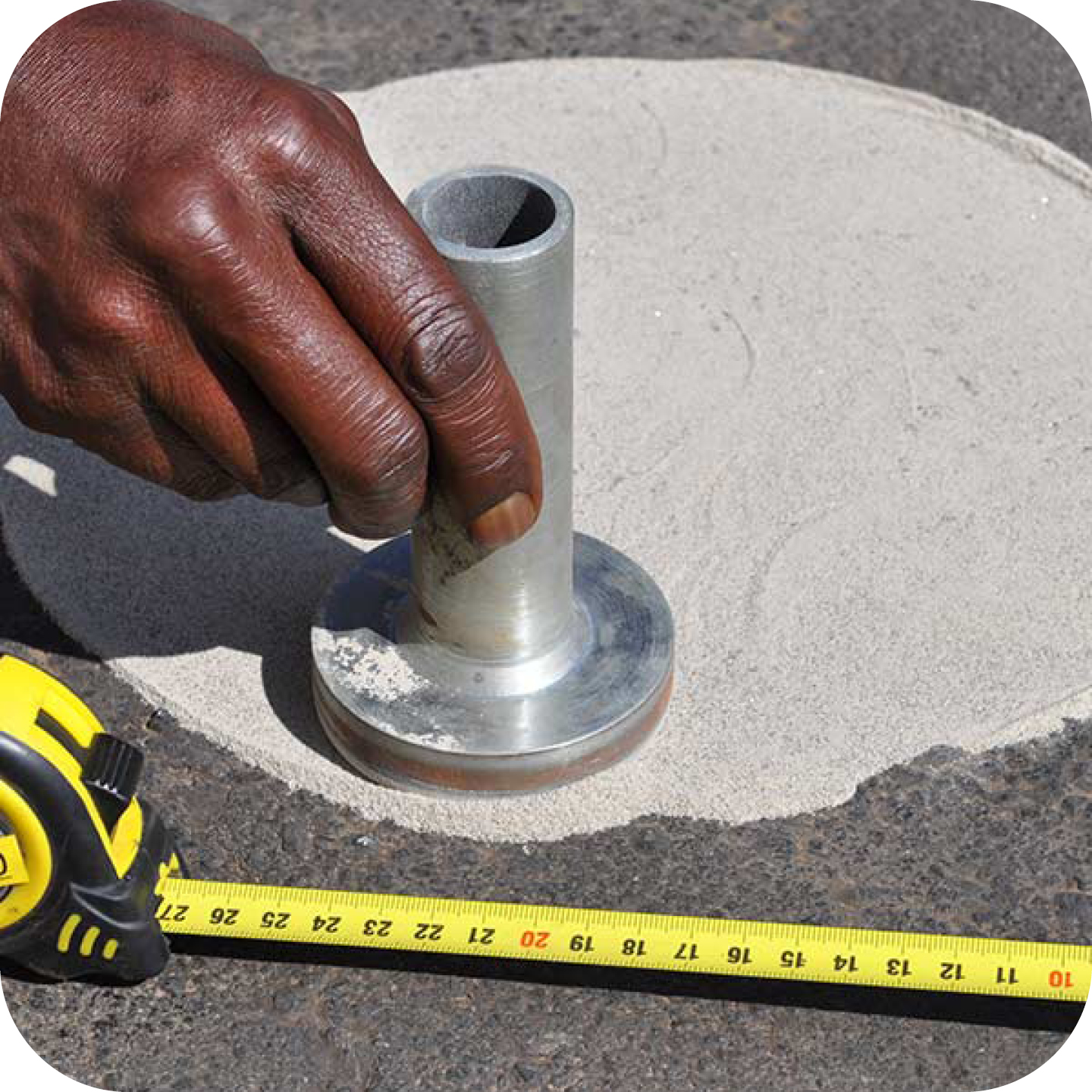

Marvil Permeability

Assesses water drainage through pavement.

Texture Depth Measurement

Measures road surface texture depth.

Walking Profilometer

Measures surface texture and smoothness.

IRI (International Roughness Index)

Rates pavement ride quality and roughness.

In-Laboratory Testing

In-lab asphalt testing offers precise, controlled analysis of asphalt materials, allowing for a deeper understanding of long-term performance, durability, and structural integrity.

It verifies critical characteristics like binder content, air voids, and moisture, as well as sample stability and elasticity.

Tests such as Rolling Thin Film Oven (RTFO), Bulk Density, and Elastic Recovery simulate real-world stresses and aging conditions.

These insights guide decisions about mix design, compaction targets,

and material suitability.

Laboratory testing ensures compliance with project specifications and industry standards, and provides documented proof of quality for handover or future auditing.

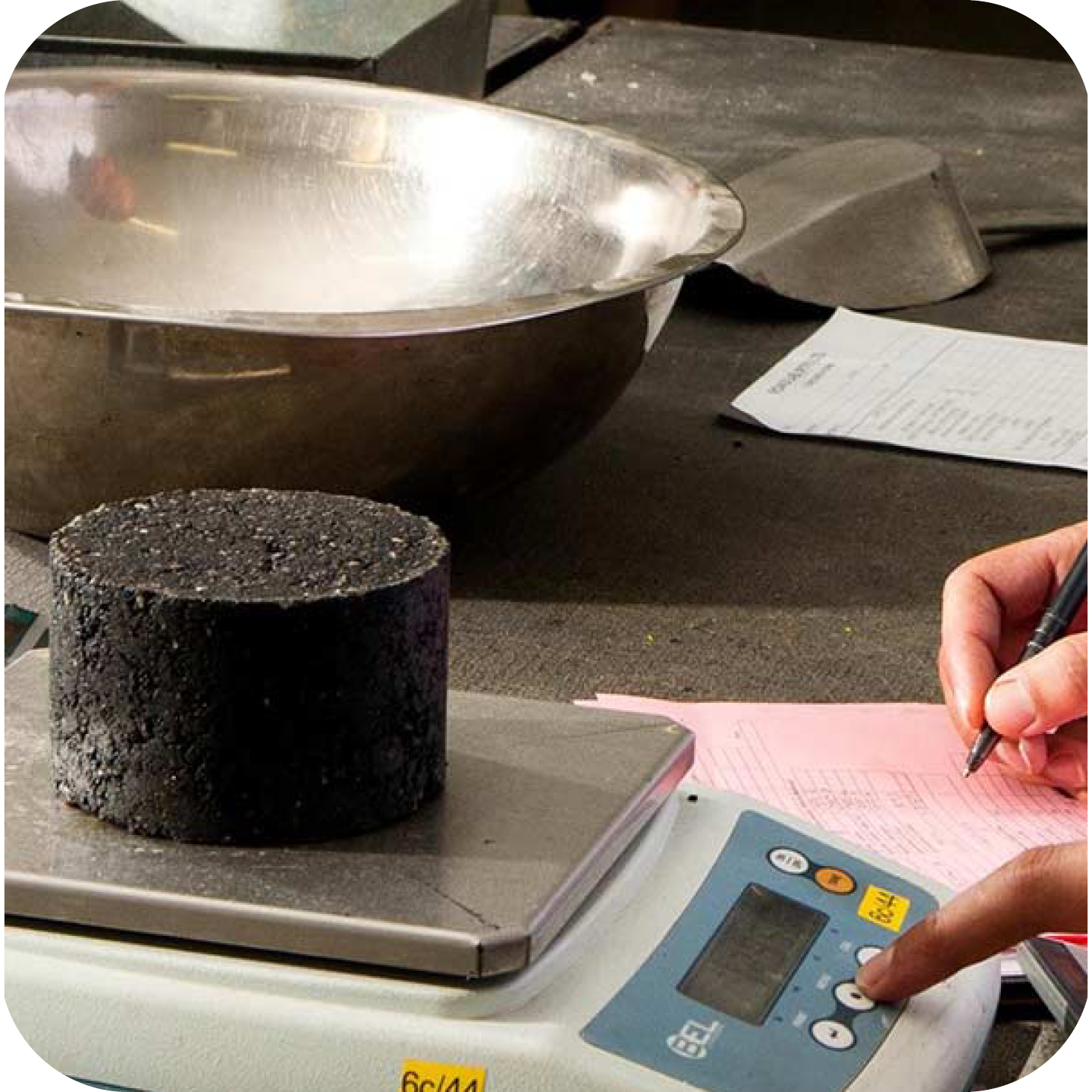

Marshall Stability, Flow & Quotient

Measures strength and flexibility of asphalt.

Maximum Theoretical Relative

Determines ideal compacted asphalt density.

Soluble Binder Content and Particle Size Analysis

Identifies bitumen quantity and aggregate gradation.

Bulk Density, Void Content

Measures compaction and air voids.

MMLS (Model Mobile Load Simulator)

Simulates traffic loads on asphalt samples.

Hamburg Wheel Track Test (Abrasion)

Evaluates rutting and moisture damage resistance.

Gyratory Compaction

Replicates field compaction in lab conditions.

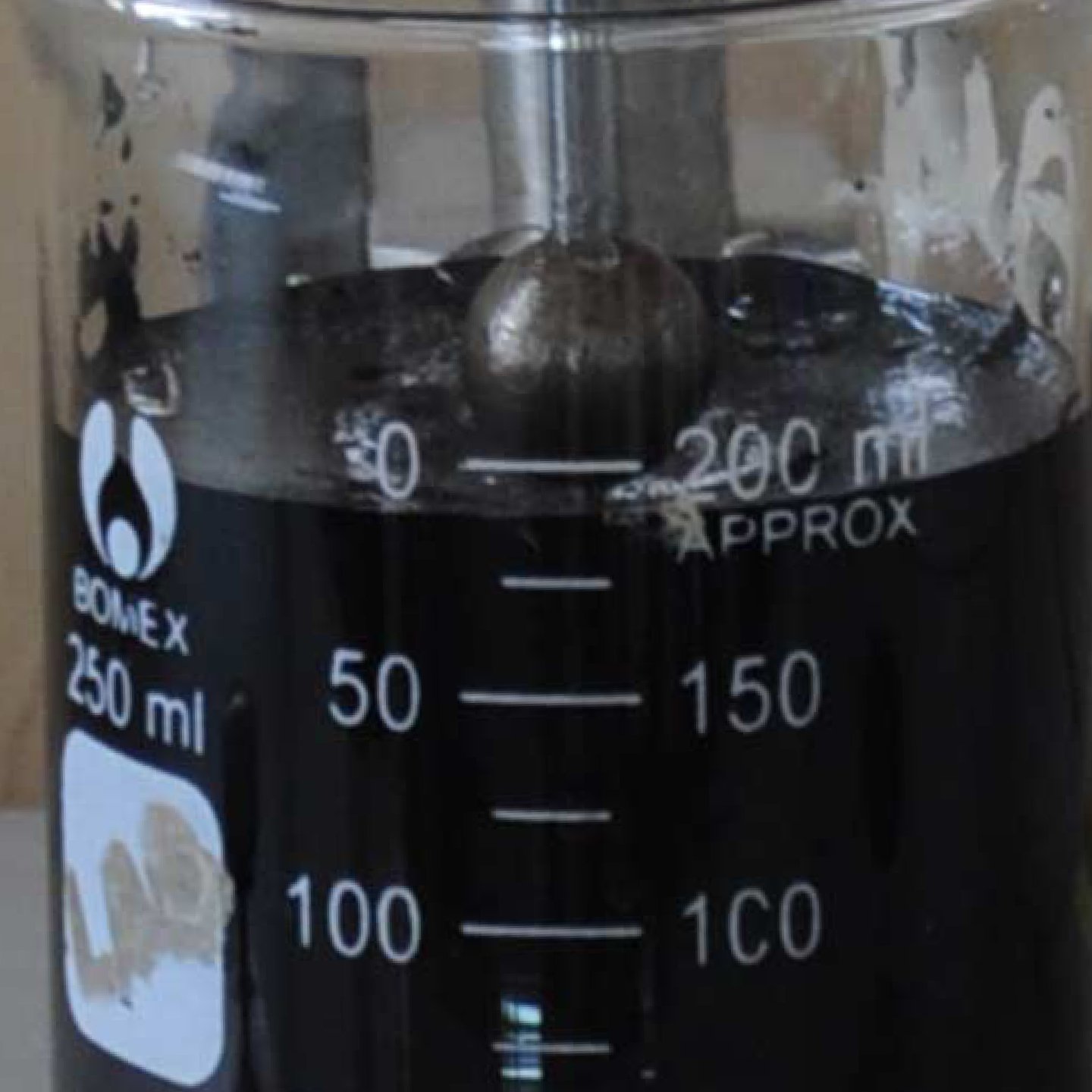

Bitumen Testing

Bitumen tests measure the resilience, flexibility, and long-term performance of the asphalt binder and the paved surface.

These assessments ensure that the surface can withstand traffic loads, resist deformation, and drain water effectively — all key indicators of road safety and durability.

By understanding how the bitumen in a asphalt surface behaves, teams can prevent cracking, rutting, and early failure — ensuring the road delivers value over its expected lifespan.

Elastic Recovery

Tests binder flexibility after deformation.

Water Content

Measures moisture in bitumen or mixtures.

Rolling Thin Film Oven Test (RTFOT)

Simulates aging during asphalt mixing process.

Compression Recovery

Evaluates binder’s rebound after compression.

Softening Point

Achieving a specific moisture content or simulating curing.

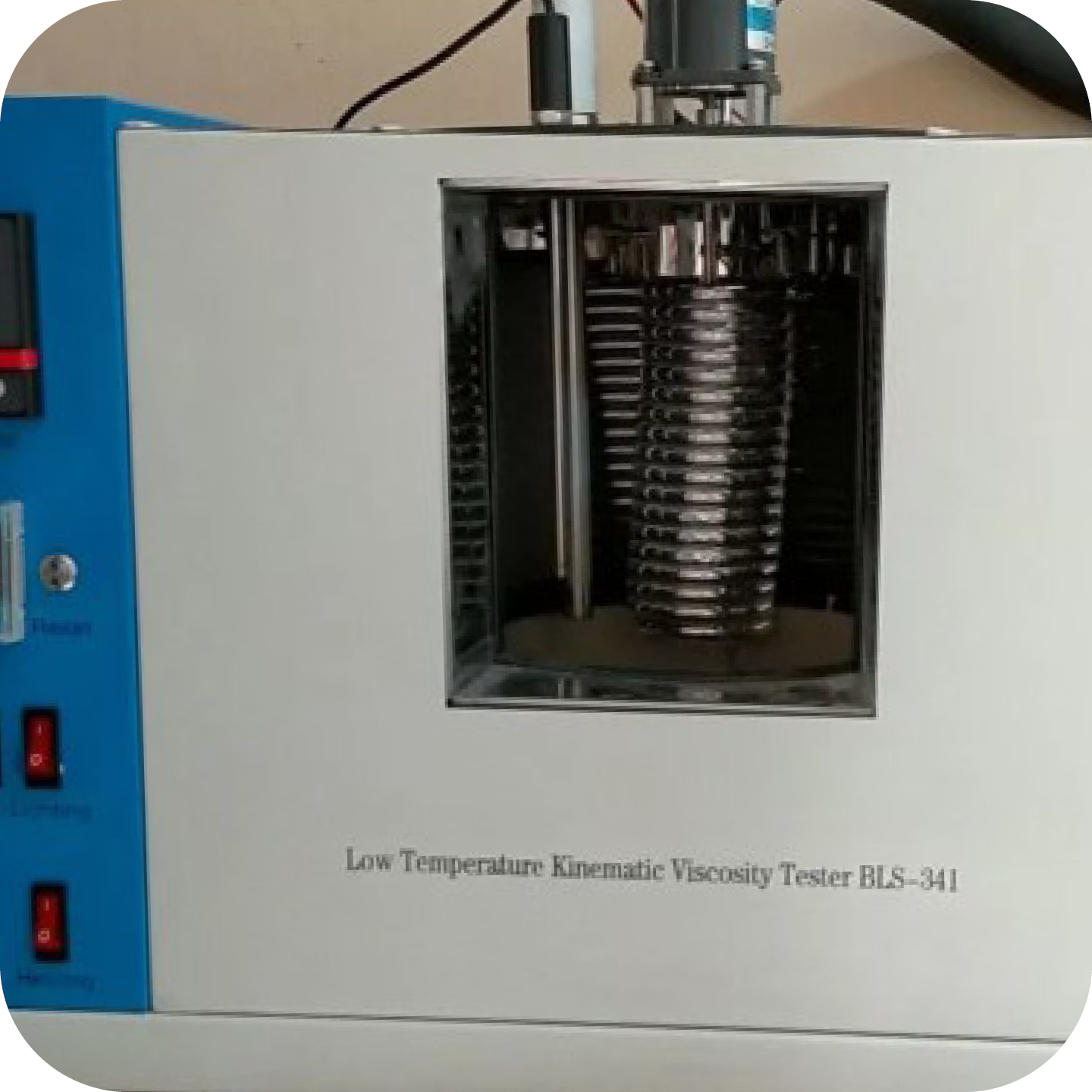

Low Temperature and Dynamic Viscosity

Assesses flow at low and high temperatures.

Needle Penetration of Bitumen

Measures binder hardness and consistency.

Ball Penetration and Resistance

Evaluates softness and resistance to load.