OUR ROLE IN

LESOTHO’S LANDMARK PROJECTS

A trusted laboratory active on Lesotho's largest projects, offering the broadest range of testing services for geotechnical and soil investigations, concrete and asphalt evaluations and more quality assurance testing.

Supporting the Lesotho Construction Industry

ON-SITE AND LABORATORY TESTING

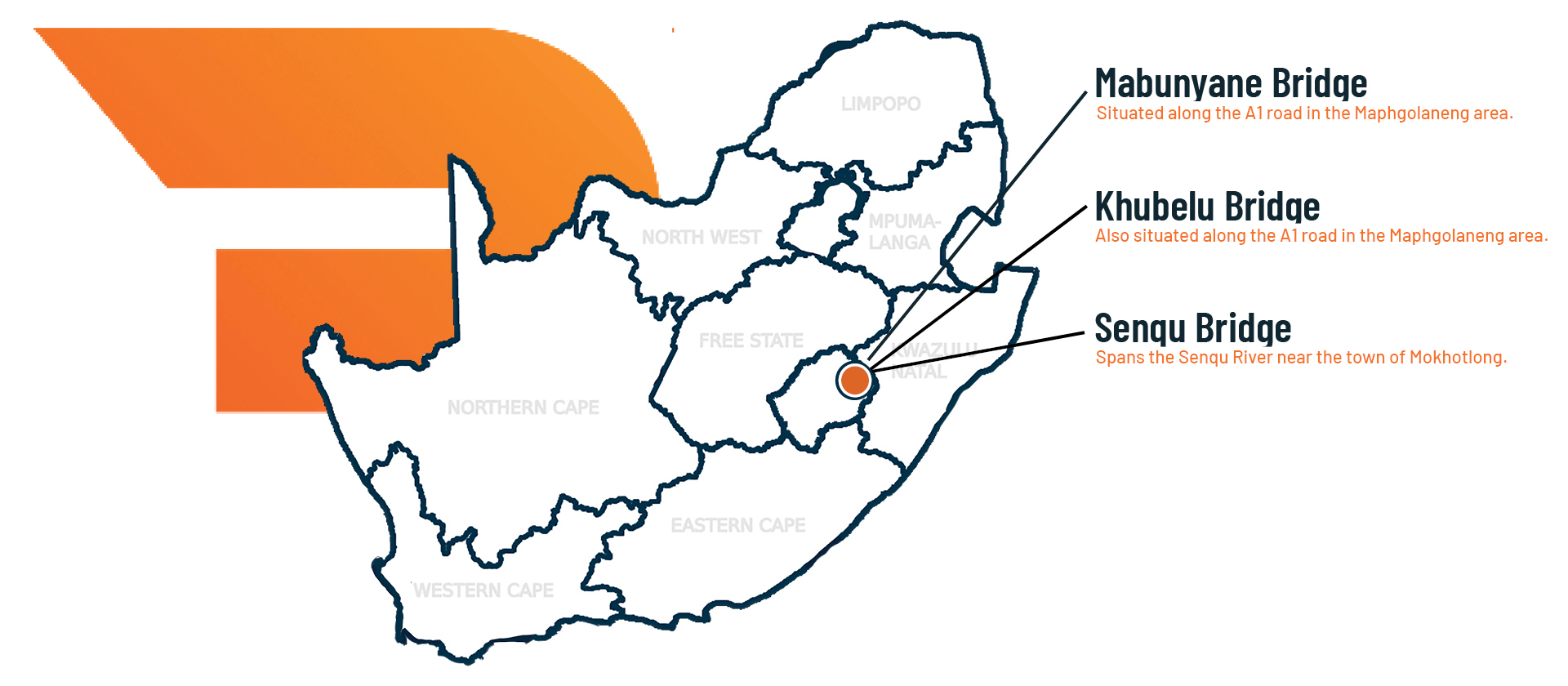

LUSIPII: 3 New Mega-Bridges in Lesotho

The Lesotho Highlands Water Project (LHWP) Phase II is one of the most significant water infrastructure developments in Southern Africa, enhancing water transfer capacity between Lesotho and South Africa.

The construction of 3 bridges under Lesotho Highlands Water Project Phase II is a complex undertaking requiring extensive civil engineering solutions to adapt to steep terrain, variable soil conditions, and high-altitude construction challenges.

By combining on-site real-time testing with advanced lab analysis, the Senqu, Mabunyane, and Khubelu Bridges are being constructed with precision, safety, and long-term sustainability in mind.

The Latest Infrastructure in Lesotho Highlands Water Project Phase 2

The Polihali to Katse Transfer Tunnel and Polihali Dam, which will create a 5042ha reservoir at the confluence of the Senqu and Khubelu rivers, are the main water transfer infrastructure works of Phase II of the Lesotho Highlands Water Project.

New roads and bridges - including Mabunyane, Khubelu and now Senqu Bridge - will form part of a larger network of infrastructure for the project.

On-site Work

With elevations exceeding 2,000 meters and sections of the river valley reaching depths of over 100 meters, ensuring the stability and longevity of this project requires meticulous planning, precise engineering, and rigorous materials evaluation.

To support this, Roadlab has established a dedicated site laboratory, allowing for real-time analysis of soil, aggregates and concrete samples at all three bridge locations.

At each site, density testing has been conducted to verify compaction levels in road embankments and bridge foundations.

Dynamic Cone Penetrometer (DCP) testing has also been essential in assessing soil strength and load-bearing capacity, ensuring that foundation structures are properly supported.

Continuous sampling for material classification has allowed engineers to select the most suitable aggregates and fill materials for embankments and structural components.

Concrete placement at high-altitude locations requires careful monitoring of consistency and workability, which is why slump testing has been performed for each major concrete pour.

Additionally, Unconfined Compressive Strength (UCS) testing has been applied to assess the stability of soil and rock formations, helping to prevent long-term settlement and structural failures.

A Lesotho Infrastructure Project of a Lifetime

These bridges, alongside the LUSIP II project, represent key milestones in Southern Africa’s infrastructure development, supporting economic growth, improved transportation, and enhanced water security.

The Senqu Bridge, the largest of the three, is set to span approximately 825 meters, making it one of the longest bridges in the region.

The Mabunyane Bridge and Khubelu Bridge, though smaller, will also play key roles in ensuring uninterrupted connectivity across the Polihali Dam basin, particularly when the reservoir reaches full capacity.

These structures are being built along the A1 road near Mokhotlong, a critical route in Lesotho’s highlands, and will improve long-term access for local communities.

Dedicated Laboratory Work

While on-site testing provides immediate quality control, laboratory analysis is essential for long-term material performance verification.

At Roadlab’s dedicated site laboratory, concrete cube strength testing has been performed to ensure that mix designs meet compressive strength requirements before full-scale construction progresses. These tests have been crucial in validating the performance of bridge deck and support structures.

Further lab work has included the making and curing of concrete cubes for extended strength monitoring, as well as UCS testing for stabilized soil samples.

As construction moves toward later phases, asphalt testing will also be introduced, ensuring durable road surfaces that can withstand heavy traffic and environmental exposure in the high-altitude region.

A Dedicated Facility in the Highlands

As we continue to support the Lesotho Highlands Water Project Phase II, our dedicated on-site team will provide ongoing testing and consultation services, upholding the highest standards in materials integrity and construction excellence.

Our work on the Mabunyane, Khubelu and Senqu Bridge reinforces our expertise in large-scale civil, geotechnical, and materials testing, ensuring that every structure stands the test of time.

Our dedicated teams are ready to answer your questions. Reach out to us today!