OUR PLACE IN

THE EASTERN CAPE

A trusted laboratory offering the Eastern Cape's broadest range of testing services, our accredited facilities are equipped to perform all your quality assurance testing.

Supporting the Eastern Cape Construction Industry

ON-SITE AND LABORATORY TESTING

Leading Quality Assurance in the Eastern Cape

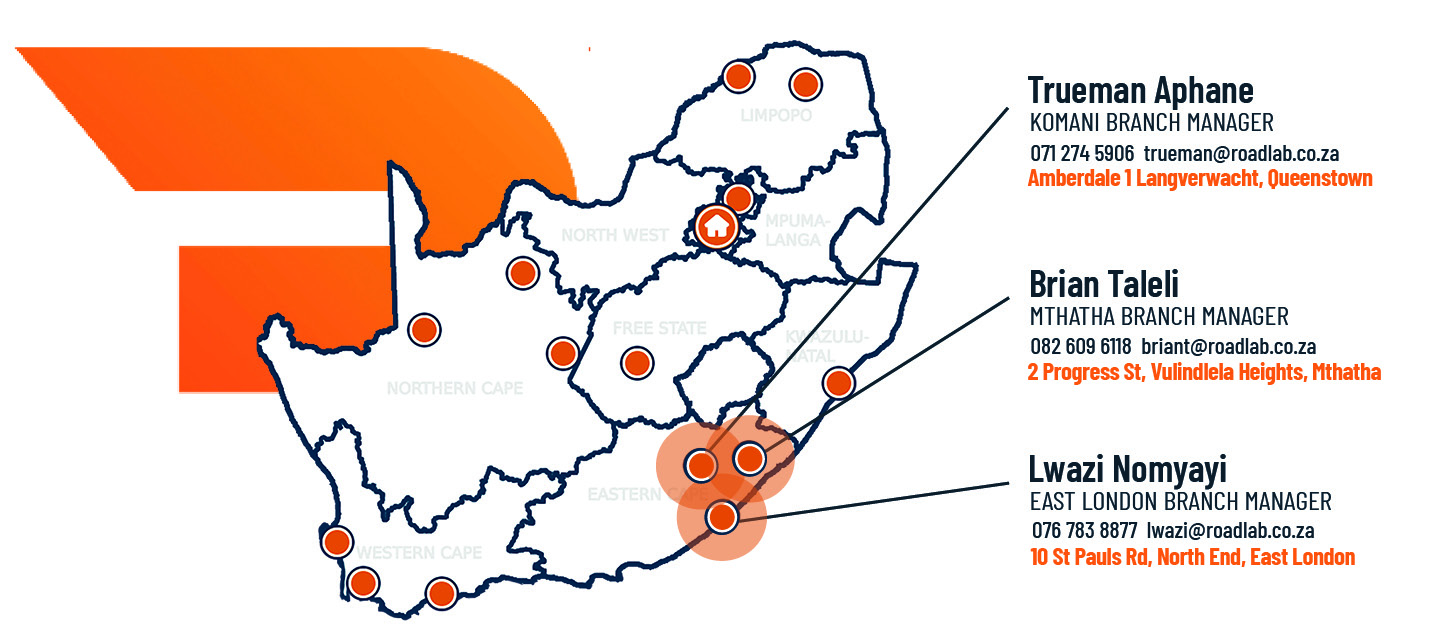

Our commercial branches in East London, Mthatha and Komani (formally Queenstown) serve construction partners across the Eastern Cape with daily quality assurance testing, enabling the building of civil projects such as housing developments, industrial zones, major roads, shopping centres, bridges, reservoirs and more.

Alongside our commercial branches, our dedicated project laboratories are supporting the province’s most significant projects, including the 400 hectare Industrial Development Zone and multi-year upgrades to the N2.

In July 2024 SANRAL announced the opening of the N2 Belstone Interchange and route MR0688 linking Bhisho to Zwelitsha, a 33-month project that Roadlab supported to address high accident rates and the traffic congestion.

Our 60th anniversary in 2025 comes at the perfect time.

Supported by state-of-the-art technology like the Mastersizer 3000E in our Johannesburg lab, we are positioned to support the Eastern Cape construction industry with new levels of precision and reliability.

Our facilities in East London, Mthatha and Komani are being prepared to host members of the construction industry with an organised focus on education around addressing key issues affecting the reliability of essential construction processes in the region.

Next year promises to be an exciting chapter in our journey in the Eastern Cape.

To understand more about the work we do in the Eastern Cape, continue reading!

On-site Testing

On-site soil testing provides real-time insights into the prevailing soil conditions at roadworks and major construction sites, guiding engineers in making informed

decisions about the soil and environment’s suitability.

Some tests, like nuclear densities, sand replacement testing, test pits and soil sampling typically requires more than a single investigation to provide the

necessary results and perspective.

Other tests, like Plate loads, Dynamic Cone Penetrometer (DCP) and Deep Probe SuperHeavy (DPSH) testing, need only be performed once or twice in order to generate a meaningful picture.

Excellent soil sampling practice is critical to ensure the integrity of testing back in the lab.

The Soils Laboratory

Preparation, analysis and reporting continues uninterrupted back at our soils laboratories in East London, Mthatha and Komani.

The California Bearing Ratio (CBR), Unconfined Compressive Strength (UCS) and Indirect Tensile Strength (ITS) testing reveals the engineering properties of soil, such as its load bearing capacity.

The PI Section of a soil laboratory provides professionals with insights into how the soil will behave under varying moisture conditions.

These more delicate evaluations include the shrinkage limit, liquid limit, plastic limit and plasticity index.

A Full-Scope Concrete Laboratory

Our in-field and laboratory concrete testing helps engineering professionals assess their materials, understand their sites, plan their work and improve their project’s chances of success.

In the field, tests such as the slump test are conducted to measure the consistency and workability of fresh concrete to ensure that it conforms to the mix design.

In the laboratory, more detailed analyses, including compressive strength, flexural strength and tensile strength tests, provide data that is crucial for designing safe and durable structures.

Proper concrete sampling involves taking a representative sample of freshly mixed concrete to make cube specimens or extracting cores.

Concrete cores provide a more comprehensive understanding of in-situ concrete, allowing for detailed analysis of its physical and chemical properties. This includes testing for compressive strength, density, and the presence of any contaminants or deleterious materials.

Concrete cubes, typically 150mm in size, are molded from fresh concrete and cured under controlled conditions before testing. Proper curing and handling of concrete cubes are crucial to obtaining accurate results.

Regular sampling and testing throughout a project ensures consistent quality and performance, minimsing the risk of potential rework, delays and structural issues.

Concrete laboratories also conduct concrete mix design tests to ensure the proper ratio of the aggregates and water testing required to conform to potability. Mix designs are tailored to meet specific project requirements, considering factors such as environmental conditions, load-bearing needs, and longevity.

Centreline Investigations

Centreline investigations involve a series of tests and procedures to determine the characteristics and suitability of soil along a planned road alignment.

Nuclear Densities assess the compaction of the soil, Dynamic Cone Penetrometer (DCP) tests provide a measure of the in-situ strength of the soil layers while hand-dug test pits allow for direct observation and analysis of soil strata and conditions.

Back in the laboratory, we assess the samples from our test pits to determine critical information regarding moisture, subgrade strength and compressive strength to inform the work of road engineers and construction professionals.

Borrowpit Investigations

Borrowpit investigations are essential to assess the suitability of local soil and gravel for use in roadworks.

Key procedures include Excavator Test Pits, Dynamic Cone Penetrometer (DCP) tests, MDD (Maximum Dry Density, known as a MOD) tests and California Bearing Ratio (CBR) tests.

A Borrowpit Utilisation Plan outlines how the resources from the borrowpit will be extracted and used efficiently while minimizing environmental impact.

Asphalt Testing for Roadworks Construction

Asphalt is a key material in road construction and maintenance, playing a vital role in ensuring the durability and safety of roads. Our cutting-edge laboratory and field testing services provide valuable insights for road construction, pavement management, and rehabilitation projects across the Eastern Cape.

Core Sampling and Analysis evaluates the quality and consistency of asphalt layers in existing pavements.

Compaction Testing evaluates the density and void content to ensure that asphalt layers are correctly compacted for maximum strength and durability.

Marshall Stability and Flow Testing measures the strength and flexibility of asphalt, assessing its ability to withstand load and stress.

Bitumen Testing assesses the properties of the bituminous binder used in the asphalt, including penetration, softening point, and viscosity, to ensure it meets required specifications.

Asphalt Performance Testing includes tests for stiffness, fatigue resistance, and rutting susceptibility to ensure the material can handle varying environmental and traffic conditions.

Welcoming Roadlab Mthatha

In 2024 long-time Branch Manager Brian Taleli became Director of Roadlab Mthatha.

This is a significant milestone for both Brian and the entire Roadlab team in Mthatha.

Their strong technical foundation and understanding of the local construction landscape has made them an indispensable resource for many construction professionals in the region, and we expect that this development will mark an exciting new chapter for our Mthatha branch and our presence in the Eastern Cape.

Our dedicated teams in the Eastern Cape are ready to answer your questions. Reach out to us today!