LEADING THE

CONVERSATION ABOUT QUALITY

This month, Roadlab’s teams have continued to demonstrate the depth of technical expertise and innovation that define our testing network — both in the field and on the international stage.

Our teams return from Tanzania today, having completed the establishment of a dedicated on-site cement laboratory, and at home we presented new research and validation studies at two national conferences, reinforcing Roadlab’s position at the forefront of scientific accuracy and standardisation.

TRUST IT.

NEXT-LEVEL MATERIAL SCIENCE

Engineering Confidence: New Frontiers

This month, Roadlab’s teams have continued to demonstrate the depth of technical expertise and innovation that define our testing network — both in the field and on the international stage.

Our teams return from Tanzania today, having completed the establishment of a dedicated on-site cement laboratory — a milestone that expands Roadlab’s role in ensuring quality at the source of production.

At home, our specialists presented new research and validation studies at two national conferences, reinforcing Roadlab’s position at the forefront of scientific accuracy and standardisation.

Roadlab returns to Dangote Cement Factory in Tanzania

In October 2025, Roadlab’s technical team travelled to Dangote Cement’s facility in Mtwara, Tanzania,

to complete the setup and commissioning of a dedicated on-site cement testing laboratory.

The laboratory, designed to deliver accredited testing at the source of production, will support one of Africa’s largest cement operations — supplying materials for major regional infrastructure projects, including the Afungi LNG development in northern Mozambique.

“Our role is to ensure consistent, verifiable quality from source to site. By embedding testing within the production process, we’re improving control, reliability, and traceability before a single load leaves the factory.”

This initiative follows Roadlab’s initial visit in August, when site layout, equipment selection, and accreditation planning began. Once complete, the Mtwara facility will perform physical and chemical testing under ISO/IEC 17025 standards, strengthening quality assurance throughout Dangote’s cement supply chain.

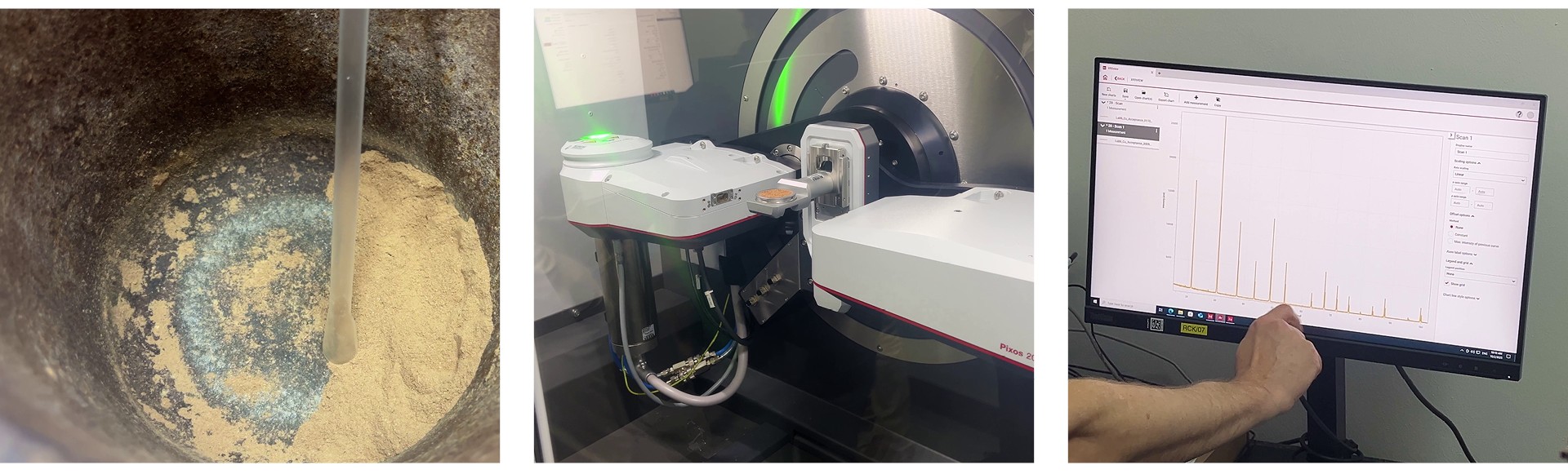

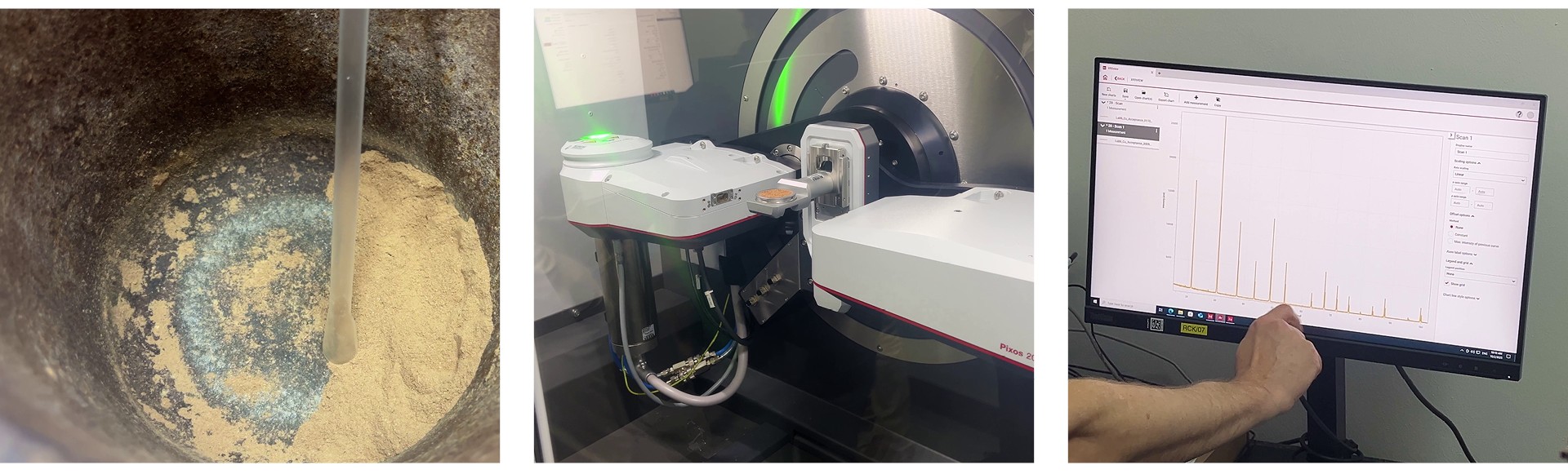

Mastersizer 3000E Validation Study

At the T&M Conference, Group Quality Manager Janco Potgieter presented Roadlab’s multi-laboratory study

comparing traditional hydrometer particle size analysis with next-generation laser diffraction using the Malvern

Mastersizer 3000E.

“We’re not replacing the science — we’re refining it,” Potgieter noted. “Our goal is to ensure every result we issue,

no matter the method, reflects the same level of trust and traceability.”

The study — performed across three laboratories following SANS 3001, ASTM D422, and BS 1377 standards —

demonstrated that the Mastersizer delivers faster, more repeatable, and more operator-independent results

than the hydrometer method.

Our presentation concluded that laser diffraction is fit for purpose in soil testing — particularly when supported

by robust quality controls under ISO/IEC 17025 — and that it represents a forward step toward harmonising particle size standards for the next generation of testing.

Building A Living Quality Management System

SAQI National Quality Conference 2025 - CSIR International Convention Centre, Pretoria

Janco Potgieter presented at the SAQI National Quality Conference in October, sharing insights into how Roadlab’s integrated Quality Management System (QMS) anticipates risk and reduces non-conformances across its national network of more than 60 accredited laboratories.

“Quality is not a department — it’s a shared responsibility,” Potgieter explained.

“Our system lives through the people who apply it every day, and that’s what keeps our results reliable.”

His presentation, “Building a Living QMS that Anticipates Risk and Reduces Non-Conformances,” explored how

Roadlab’s QMS acts as a living system — continuously adapting through data-driven feedback, proactive training,

and real-time process control.

Rather than existing as static documentation, Roadlab’s QMS connects technicians, quality officers, and managers through constant feedback loops. The result is early identification of risk, improved consistency, and greater

confidence in every result delivered.

A New Era: From Innovation to Real-World Application

Through the establishment of a fully equipped cement testing laboratory in Tanzania and the presentation of new research that advances industry standards, we’re strengthening the reliability of testing across every discipline.

Each milestone reflects Roadlab’s growth, from traditional testing experts to leaders in the role and future of quality assurance in South Africa.

As we expand into new regions and roles, our focus remains clear: to uphold accuracy, consistency, and trust — the principles that define Roadlab and the results our clients depend on.