YOU ARE ENTERING

THE FUTURE OF MATERIAL TESTING

October saw the conclusion of the Mabunyaneng and Khubelu Bridges in the Lesotho Highlands, the 14-year Kusile Power Station programme in Mpumalanga and vital national and regional corridors in the North-West and Free State — each strengthened by Roadlab’s accredited testing.

TEST IT.

NEXT-LEVEL MATERIAL SCIENCE

A New Era for Material Analysis

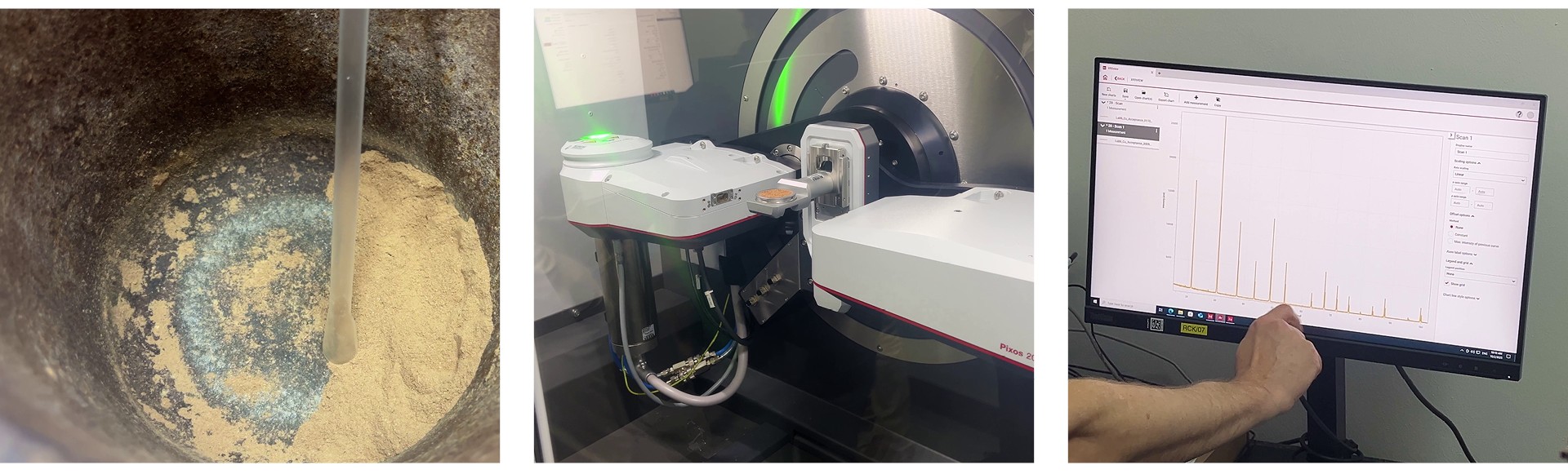

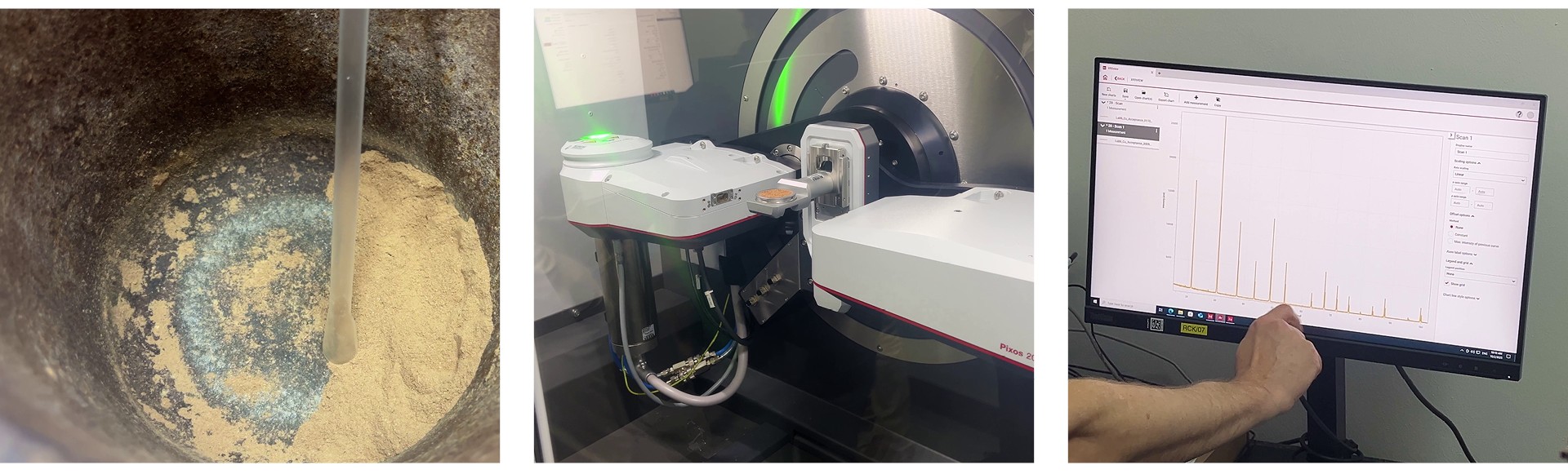

The Roadlab Rock Mechanics Unit officially entered operation this month.

Over three days, our specialists worked alongside international trainers to complete setup and system calibration of our Anton Paar XRDynamic X-Ray Diffractometer (XRD) — the first of its kind in Africa.

The XRD now allows Roadlab to determine mineral composition and crystalline structure to near-atomic levels.

Supported by our Malvern Mastersizer 3000E and Anton Paar Gas Pycnometer, our suite of advanced analytical tools can reveal particle size, porosity, and density with unmatched precision, extending far beyond traditional testing and supporting everything from pavement design to geotechnical work.

NME: The Future of Roads

Roadlab is helping lead South Africa’s adoption of Nano-Modified Emulsion (NME) technology — a next-generation pavement stabilisation approach that delivers more water-resistant and durable layers.

Our Germiston branch and Tshikanosi Project Laboratory have been working with engineers and road-building professionals for more than 5 years to refine and validate the application of this technology.

(Our work with Aphane Consulting and ROMH).

In recent months, we’ve supported Lathiso Consulting Engineers through our dedicated Tshikanosi Site Lab - our first to perform NME design testing - using a specialised mix to evaluate stabilisation performance and hydrophobic response.

We have also served Buzaphi Construction in Giyani and MRT Global in Delmas with NME design verification, NME laboratory support and durability and strength verification on field cores to assess long-term behaviour under traffic and moisture exposure.

These projects mark a critical step forward in mainstreaming NME as a sustainable, cost-effective pavement technology — and demonstrate how Roadlab’s laboratories are equipped to both test and design NME applications at a national scale.

A New Era: From Innovation to Real-World Application

Roadlab is strengthening its position as the reference point for material insight in Southern Africa.

With the addition of advanced analytical capability at Germiston and our ongoing refinement of NME technology in the field, every result we produce can be supported by by greater evidence, precision, and purpose.

Why? To support engineers with data that informs design decisions and ensures lasting performance.