ROADLAB IS

BUILDING CONFIDENCE, ONE PROJECT AT A TIME

This month, our site-laboratories have wrapped up two major infrastructure assignments in the North West and the Eastern Cape —each underscoring how accredited testing, on-site expertise and strategic partnerships deliver lasting impact.

BUILD IT.

DELIVERED PROJECTS

Delivered Projects - October 2025

This month we celebrate the completion of two significant undertakings.

Both the R27 Calvinia Special Maintenance Project in the Northern Cape and the R61 Cradock Upgrade in the Eastern Cape have concluded, thanks to accredited testing, on-site expertise, and close client partnerships.

R61 Cradock Maintenence

Manager: Enoch Ntjana

Conclusion Date: 30 October 2025

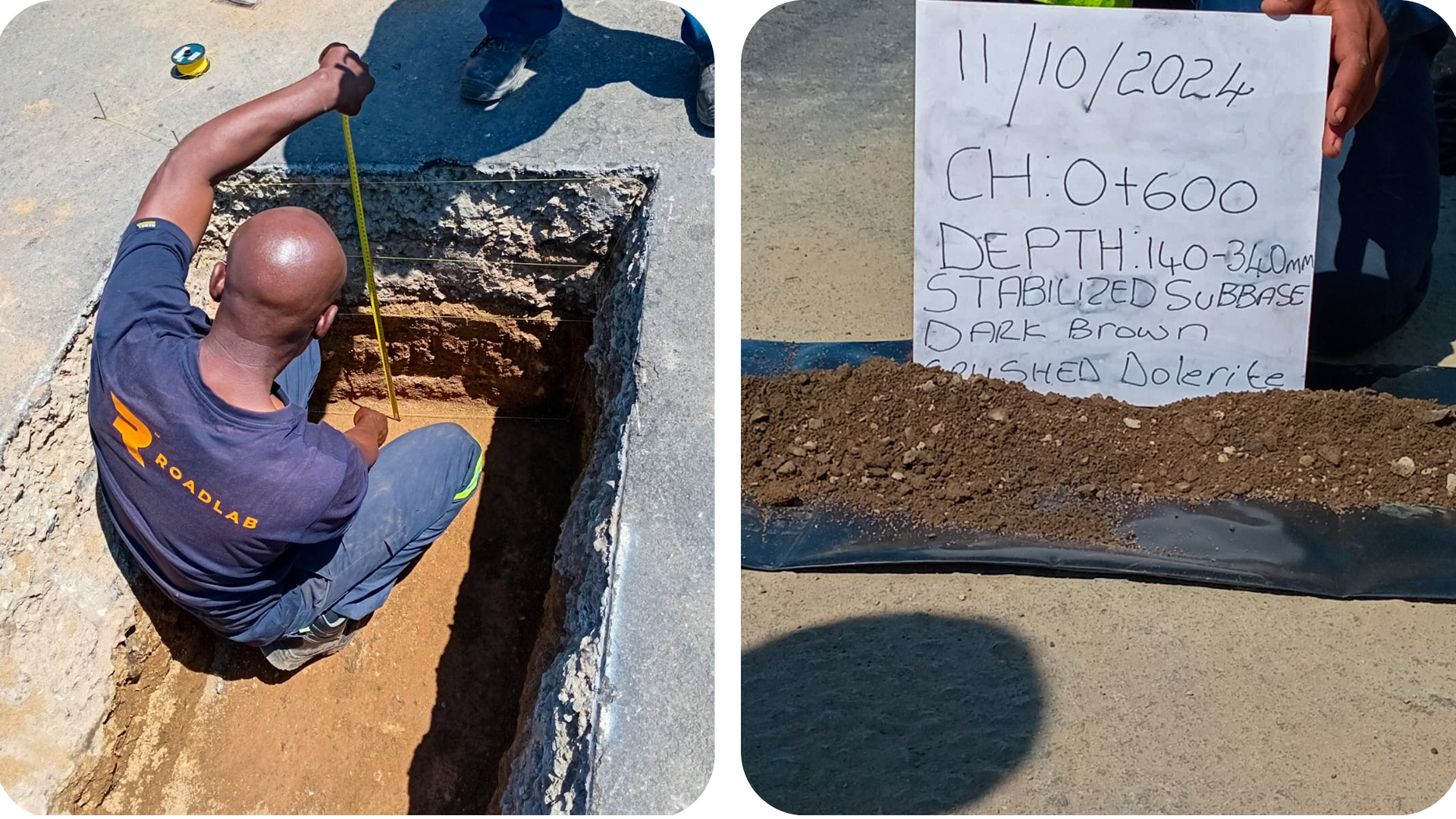

Located between Cradock and Tarkastad, the R61 Section 3 project spans 24.7 km of the national route and forms part of a vital transport corridor in the Eastern Cape Province.

The route serves both rural traffic and the dual carriageway through Tarkastad, connecting local communities to regional economic centres.

Roadlab was appointed to provide the on-site materials testing and quality control required for the project’s rehabilitation and widening works.

The upgrade includes a Cape Seal surfacing with 20 mm aggregate and double slurry and a 150 mm bitumen-stabilised base (BSM) layer. The roadbed has been prepared to 93 % MDD, ensuring a strong and uniform foundation.

In addition to the pavement layers, the project involves the construction of culverts, V-drains, stone-pitch channels, and subsoil drainage systems to improve long-term durability.

R27 Calvinia Maintenence

Manager: Sporro Tauwa

Conclusion Date: 17 October 2025

Roadlab has completed its role on the R27 Calvinia Special Maintenance Project, a SANRAL initiative to strengthen one of the Northern Cape’s most vital regional corridors.

This project included reseal works, bitumen-stabilised base (BSM) reconstruction, and asphalt surfacing, restoring full pavement integrity and ride quality across the network.

At Van Ryns Pass, one of the province’s most demanding stretches of mountain road, teams worked under unique logistical and safety pressures to deliver a 160 mm asphalt BTB layer, first rebuilding the G3 base and completing multiple structural and medium asphalt layers above.

This site laboratory provided continuous Marshall stability testing, density control, and layer verification, ensuring every section met the required compaction and quality benchmarks.

Commitment to Quality: A SANAS-Accredited Facility

At Roadlab, quality is what we do.

This commitment to excellence shapes how we support infrastructure development across the Western Cape — from dense urban upgrades to remote renewable energy builds.

By continually refining our geotechnical, concrete, and materials testing processes, we help ensure that the region’s roads, bridges, coastal structures, and wind farms are built to endure.

Our work is underpinned by strict adherence to SANAS accreditation standards, ensuring that every test we perform meets national and international benchmarks for accuracy, reliability, and compliance.

We're ready to answer your questions. Reach out below.